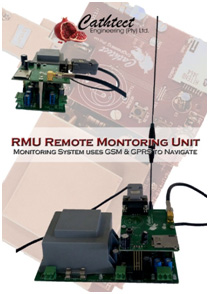

Remote Monitoring Unit (RMU)

Remote Monitoring equipmentis used to monitor Cathodic Protection Systems, gathering and providing valuable information.RMU’s are generally installed near a Cathodic Protection Rectifier but can also be installed at critical structure-to-soil potential test stations, depending on the application requirements.

The Cathtect Remote Monitoring Unit is a programmable remote controller that provides remote monitoring and control of the Rectifier Unit.

This Monitoring Unit uses GSM and GPRS to navigate & monitor corrosion around pipelines and tank structures. This enables personnel to request and collect Cathodic Protection performance information from any location around the world using cellular networks.

Personnel no longer need to travel to a site, not only is this ideal in that it saves time and travel expenses but it can also be beneficial where sites are not easily accessible. The RMU does not only measure the performance of the Cathodic Protection System, it can also pick up any faults that might occur so that it can be repaired.

The Cathtect RMU is designed to make Cathodic Protection monitoring simpler whilst still providing all the benefits. This innovative unit allows you to:

- Instantaneously request information i.e. 24-hour logs, values for control modes or alarms.

- Remotely change control settings

- Have an SMS or TEXT sent to the master station should there be any kind of fault or tampering.

The Cathtect RMU is sufficient and reliable for all monitoring and Cathodic Protection applications and needs.

Features

Power Supply/UPS Module

- Power Input: 220V AC 50Hz

- Power Outputs: 15-0-15V AC, Regulated +/-15VDC @ 100mA

- Battery Charging: 10mA trickle charger for 12VDC SLA Battery

- Provides UPS supply to the multi-mode controller and GSM module.

- Sets the “AC Supply failure to Monitoring Unit” Alarm signal on interruption of the 220 V AC supply.

GSM Module (plus antenna)

- GSM/GPRS SMS enabled Modem.

- Power Input: 12 VDC

- Standard Sim card slot (MTN/CELLC/ Vodacom/Telkom)

- Din rail mount

12V SLA Rechargeable Battery

- Provide up to 150 hours of backup supply.

Power and signal line protection

- 220 V AC power is protected by 275 V 15kA MOV

- TRU output voltage signal: 275 V 15kA MOV

- TRU output current signal: bidirectional diode across shunt input on PCB.

- Reference Potential signal: 60-0-60V 1.5kA bipolar transorb with 90V spark gap to

- Digital inputs protected to 20V continuous

Functional Description

- To continuously monitor the important outputs of the TRU.

- To detect TRU fault conditions

- To provide local automatic TRU control capability in one of four selectable modes.

- To continuously log TRU operating (and fault) conditions with the following parameters.

- To transmit via a single SMS the latest recorded 24-hour log to the Master Station including the following data.

- When polled by the Master Station or any personal cell phone, the outstation must transmit via a single SMS to the polling personal cell phone or Master station the following data.

- To transmit via SMS the following ALARM data to the Master Station.

Master Station hardware and Software

- This will consist of a desktop PC, for continuous runtime use, fitted with the following items:

- Power Supply module (socket-mounted).

- GSM Module (plus antenna).

Master Station Functional Description

The Master Station should be able to operate, manage and control up to 250 remote Transnet Pipelines Remote field units, all of which communicate via GSM SMS.

To poll any selected Outstation for the following.

- Visual Display of selected TRU latest polled data.

- Visual Display of selected TRU setup parameters.

- Visual Display of selected TRU setup parameters cont.

- Visual Display Chart of selected TRU latest received Log data.

To receive, unsolicited, from any selected Outstation the following.

- Visual Display of Alarm data from Outstation. Such as

- Data file creation and management.

- Visual Display of Support Service Contact Information

- Documentation for remote monitoring and control system.