Description

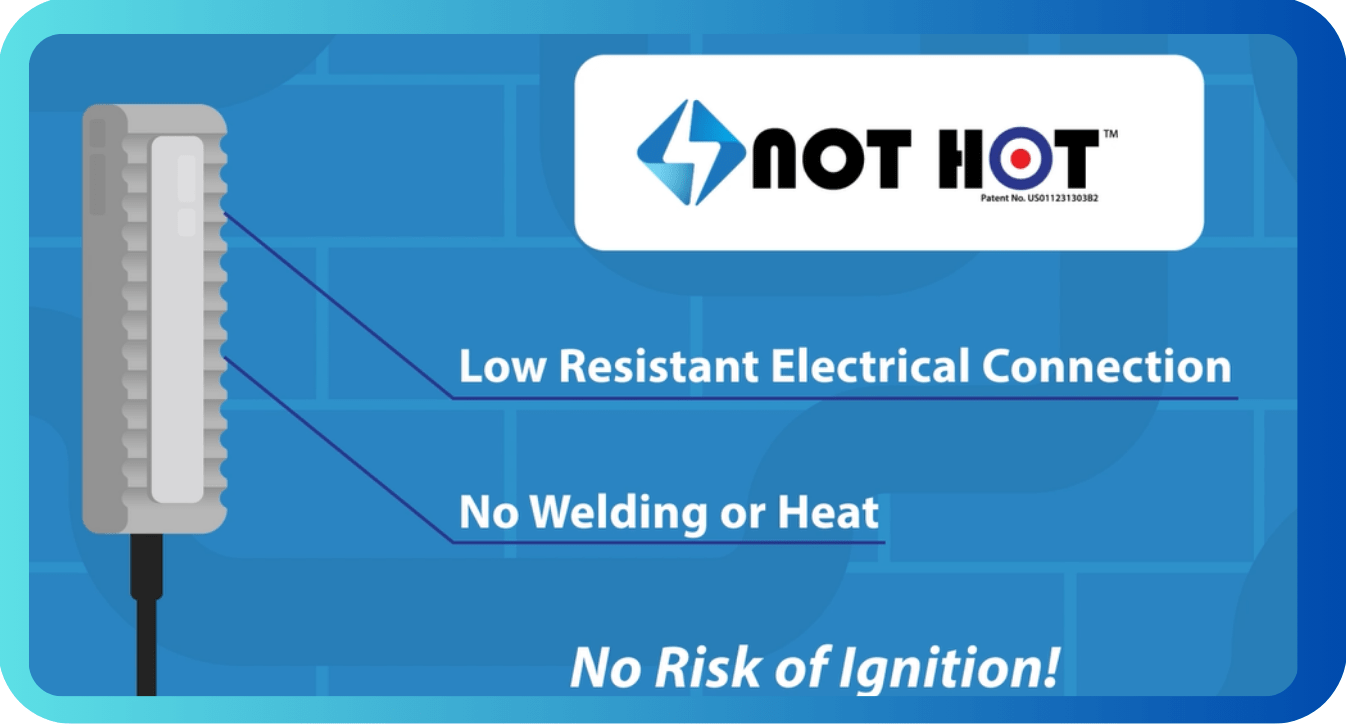

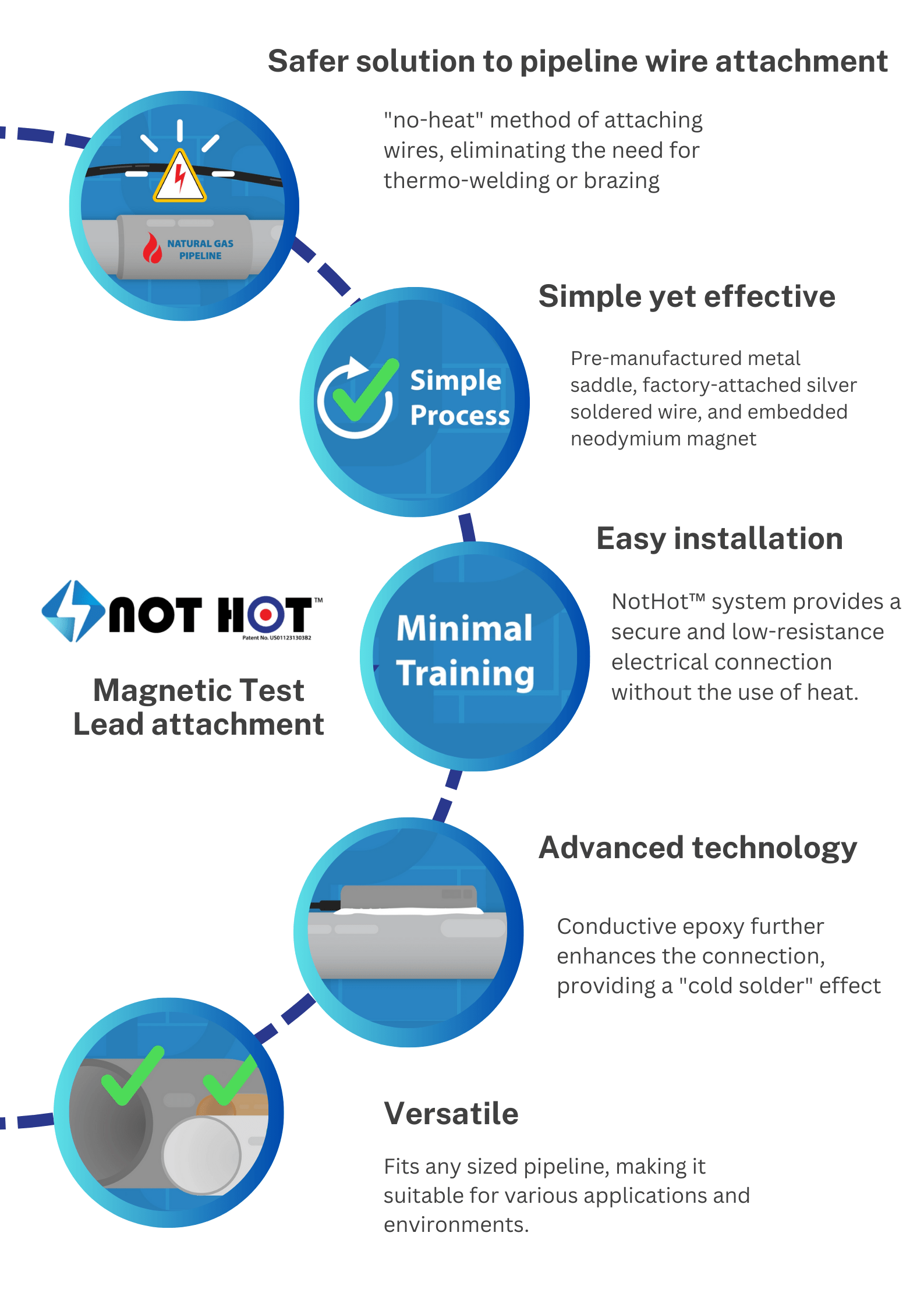

The revolutionary solution offers a safe, “no-heat” method of attaching wires to Structures, eliminating the need for welding, thermo-welding or brazing.

With a pre-manufactured metal saddle, factory-attached silver soldered wire, and embedded neodymium magnet, the NotHot™ system provides a secure and low-resistance electrical connection without the use of heat.

But what sets the NotHot™ Magnetic Test Lead Attachment apart from conventional methods? Let’s delve into its features and advantages:

- Safety First: Avoids potential damage to pipelines and reduces the risk of ignition in high-risk combustible environments, ensuring safer operations.

- Versatility: Fits any sized pipeline, making it suitable for various applications and environments.

- No Heat, No Worries: Perfect for instances where heat-related wire attachment is unsafe or undesirable, offering peace of mind without compromising efficiency.

- Minimal Disruption: With keyhole-compatible installation using the NotHot™ keyhole applicator tool, installation is swift and minimizes disruption to pipeline operations.

- Durable and Reliable: Provides a low-profile connection on the pipeline, reducing the risk of soil stress damage and ensuring long-term reliability.

- Immediate Coating Application: Coating can be applied immediately after installation, thanks to the two-part conductive epoxy that cures even after external coating patch application.

How does the NotHot™ Magnetic Test Lead Attachment work?

It’s simple yet effective. The pre-manufactured metal saddle, equipped with a silver-soldered wire and neodymium magnet, is placed on the prepared pipeline.

Conductive epoxy further enhances the connection, providing a “cold solder” effect. While the epoxy cures, the strong magnet holds the saddle securely in place, ensuring conductivity and reliability.