Introducing NotHot™ Magnetic Test Lead Attachment: A Safer Solution for Pipeline Wire Attachment

Are you concerned about the inherent risks associated with conventional approaches to wire attachment on buried metal pipelines? Troubled about potential heat damage or safety hazards in high-risk environments? Look no further than the innovative NotHot™ Magnetic Test Lead Attachment—a game-changer in the field of pipeline wire attachment.

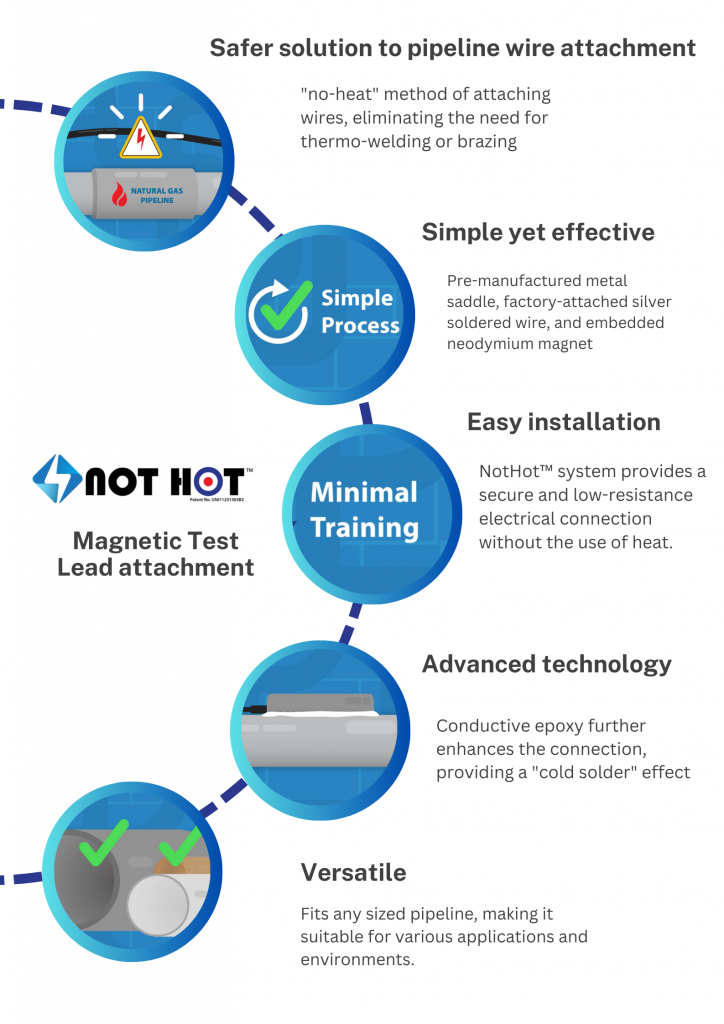

The revolutionary solution offers a “no-heat” method of attaching wires, eliminating the need for thermo-welding or brazing.

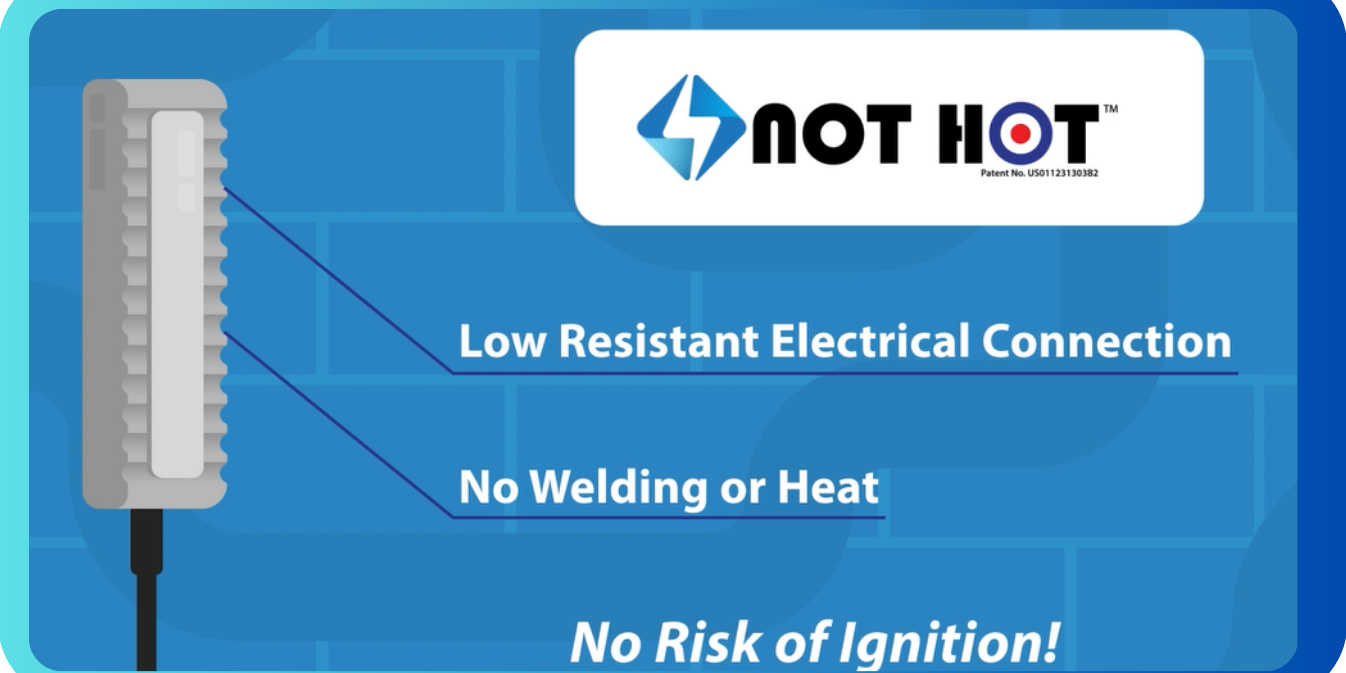

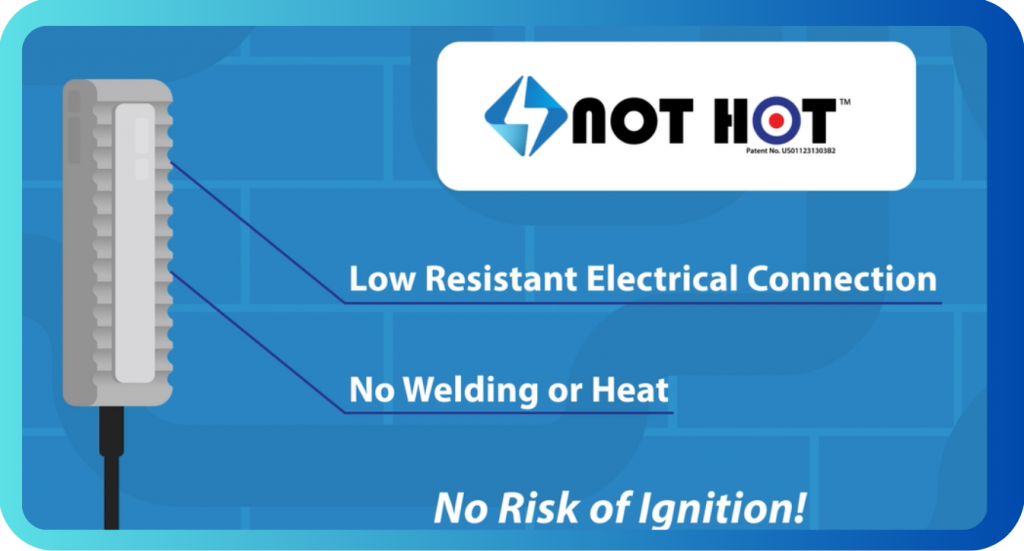

With a pre-manufactured metal saddle, factory-attached silver soldered wire, and embedded neodymium magnet, the NotHot™ system provides a secure and low-resistance electrical connection without the use of heat.

But what sets the NotHot™ Magnetic Test Lead Attachment apart from conventional methods? Let’s delve into its features and advantages:

- Safety First: Avoids potential damage to pipelines and reduces the risk of ignition in high-risk combustible environments, ensuring safer operations.

- Versatility: Fits any sized pipeline, making it suitable for various applications and environments.

- No Heat, No Worries: Perfect for instances where heat-related wire attachment is unsafe or undesirable, offering peace of mind without compromising efficiency.

- Minimal Disruption: With keyhole-compatible installation using the NotHot™ keyhole applicator tool, installation is swift and minimizes disruption to pipeline operations.

- Durable and Reliable: Provides a low-profile connection on the pipeline, reducing the risk of soil stress damage and ensuring long-term reliability.

- Immediate Coating Application: Coating can be applied immediately after installation, thanks to the two-part conductive epoxy that cures even after external coating patch application.

How does the NotHot™ Magnetic Test Lead Attachment work?

It’s simple and effective. The pre-manufactured metal saddle, equipped with a silver-soldered wire and neodymium magnet, is placed on the prepared pipeline.

Conductive epoxy, this further enhances the connection, providing a “cold solder” effect. While the epoxy cures, the strong magnet holds the saddle securely in place, ensuring conductivity and reliability.

Whether you’re working in hazardous environments, dealing with thin-walled pipelines, or simply seeking a safer alternative to traditional methods, the NotHot™ Magnetic Test Lead Attachment delivers unmatched performance and peace of mind.

Say goodbye to heat-related risks and hello to a safer, more efficient solution for pipeline wire attachment. Experience the innovation of NotHot™ today!

Contact Cathtect USA for more details and other Cathodic Protection Products and support

+1 772 646 2873 or [email protected], www.cathtectusa.com.

Or Request a quote [email protected] and our technical sales team will be happy to answer any questions and assist you in choosing the right product for all your corrosion protection application.