Concrete Corrosion Products

Cathtect ‘s primary concern is addressing the underlying root cause of concrete deterioration. We know that the # 1 cause of this deterioration is corrosion of the reinforcing steel within the buildings’ structure, so we have partnered with industry’s leading engineers and consultants and made it our mission to supply the perfect corrosion protection strategy and products to meet all our clients’ specific needs.

When designing or developing a new structure the most effective way to mitigate corrosion is to prevent it. Preventive coatings, high-quality concrete, and galvanized rebar are common preventive methods used for corrosion prevention in new structures.

Unfortunately for most asset owners, this is not an option as their preexisting concrete is already contaminated with corrosive contaminants.

Cathtect offers corrosion mitigation products for both new and already exposed concrete structures, depending on your application we can advise the best and most appropriate way to protect your existing or future investment.

Take action and let Cathtect create a customized strategy to combat your coastal structure and buildings corrosion problems today! Get in touch with us to learn more.

This Impressed current cathodic protection (ICCP) system that uses a patented mineral-based, conductive paint as the anode. Electrical current is delivered to the conductive paint using a network of Power Delivery Ribbons (PDR). The ZEBRATM anode is applied directly to the concrete by roller, brush or spray, and can be coated with a variety of traffic-bearing membranes or paints to meet aesthetic needs. The system is powered using a cloud-based control and monitoring system.

Contact us today to find out more…….

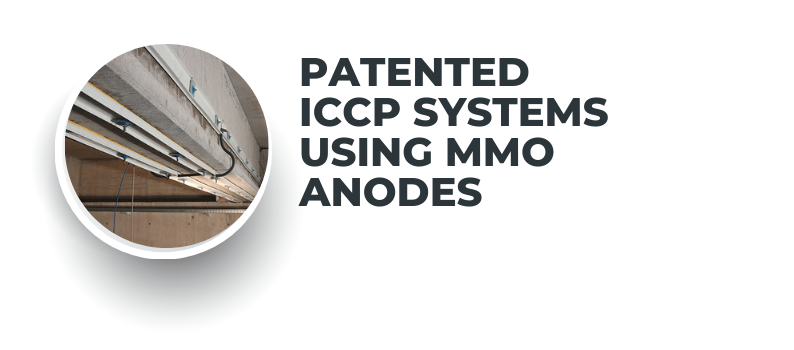

Cathtect is proud to be the supplier of a revolutionary product to the field of concrete corrosion mitigation. This patented impressed current cathodic protection system uses one or more MMO coated titanium ribbon anodes encapsulated between a fiberglass profile and a mineral wool contact felt. This is then anchored on the concrete, compressing the contact felt into the surface. Once connected to a power supply, current is discharged from the ribbon through the felt and concrete where it is picked up by the rebar thereby eliminating future corrosion.

Contact us today to find out more…….

Corrosion of the reinforcing steel is the #1 cause of concrete damage, but it is often overlooked when making local patch repairs. Cathtect supplies world class galvanic anodes that are designed to extend the life of patch repairs by providing cathodic protection to the steel in the most vulnerable area surrounding a new concrete patch. When electrically connected to the steel the galvanic anode forms a galvanic cell and preferentially corrodes/consumes, while offering cathodic protection to the steel reinforcement.Galvanic anodes can provide effective corrosion protection for up to 20 years* with no monitoring or operation required.

Contact us today to find out more…….

Coating rebar for corrosion protection is common practice in the concrete repair & restoration process. Many products require mixing & measuring of multiple components and give contractors a very small window to apply the repair mortar after the rebar has been coated. Our coatings offer contractors & engineers the best of both worlds: higher performing corrosion protection & easier application. This product is a one component, low VOC rebar coating that gives contractors the flexibility to extend open times on repairs (up to 180 days!). Using its patented self-healing technology, the coating itself responds to any physical damage during the repair open time without the need for manual intervention or touchups.

Cathtect now also supplies a self-healing primer for optimal corrosion protection. This product contains patented microcapsules encompassing a healing agent. When damage occurs, the healing agent is released from the microcapsules and the coating starts to autonomously heal itself, increasing the life of the coating up to 400%. The most common applications include:

- Exposed steel

- Cooling towers

- Aluminum railings

- Concrete

Contact us today to find out more…….