An aluminum anode is a galvanic anode and a major component of a galvanic cathodic protection system, which is used to prevent corrosion of buried or submerged metal structures such as pipelines, tanks or other related equipment. They are also classified as sacrificial anodes, which are intended to sacrifice themselves to the corrosion process, thereby leaving the rest of the system relatively corrosion-free. – Corrosionpedia

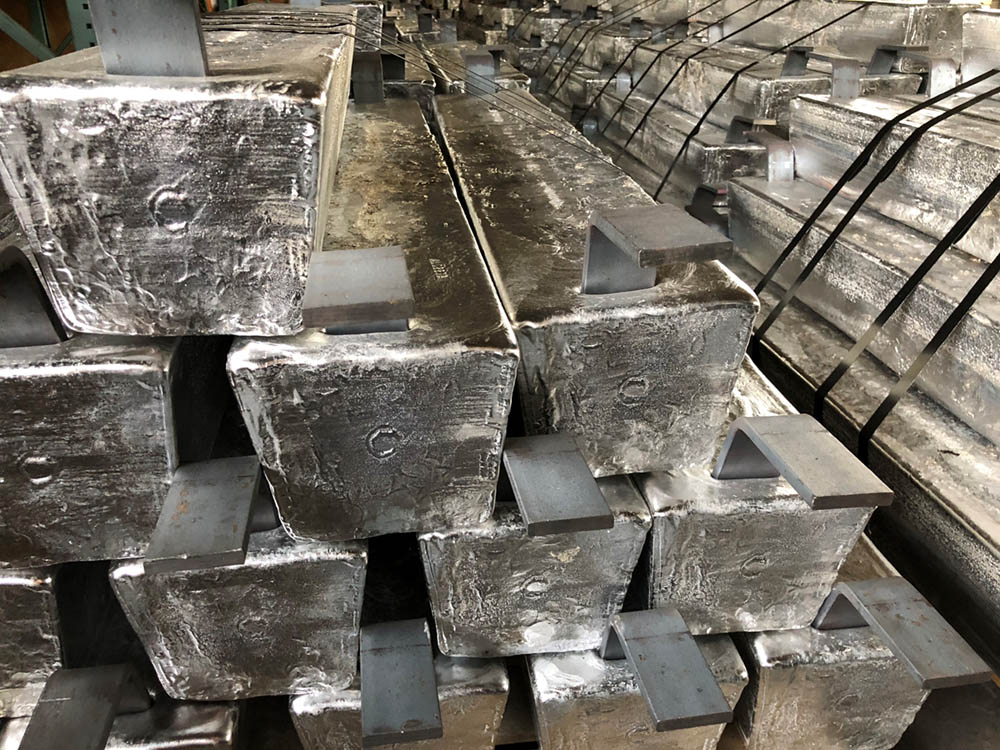

Sacrificial Anodes - Aluminum Anodes

Aluminum Anodes are commonly utilized in saltwater or marine environments where Cathodic Protection is essential. The suppliers of Cathtect USA meet or surpass industry standards and have the ability to create any standard or personalized anode type that you may need.

The anodes are produced in a laboratory that holds ISO 17025:2005 accreditation to guarantee quality concerning chemical composition and electrochemical performance. Chemical composition analysis is performed on each heat before casting. Optical Emission Spectroscopy is utilized for chemical analysis.

Custom Anode Alloys can be manufactured according to specific requirements upon request.

Electrochemical Properties are evaluated using industry-standard methods such as Nace TMO-190, ISO, and/or DNV RP-B401.

Aluminum anodes offer several benefits in galvanic cathodic protection systems, such as:

- Ensuring the corrosion protection of reinforcement rods.

- Preventing corrosion on older structures that show no signs of deterioration.

- Enhancing the durability of new structures.

- Requiring minimal maintenance.

- Providing an alternative to using a zinc coating or plating to shield metals and existing structures from corrosion.

Aluminum anodes can be produced with diverse core configurations to meet various anode specifications and applications. Whether you need anodes for a new structure or to upgrade an existing platform, Cathtect USA can supply anodes tailored to your specifications.

Aluminum has a diverse range of applications, including transportation (cars, airplanes, trucks, trains, ships, etc.), packaging (cans, foil, etc.), construction (windows, doors, siding, etc.), consumer durables (appliances, cooking utensils, etc.), electrical transmission lines, machinery, and many other areas.