The Role of Magnesium Drive-In Anodes in Solar Panel Applications

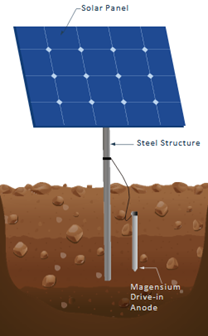

In the realm of solar energy, pilons, buried stanchions and metallic post installations. the efficiency and longevity of the infrastructure are paramount. One of the lesser known yet critical components in safeguarding the durability of solar panel systems is the use of cathodic protection, specifically magnesium drive-in anodes. This post delves into the need for these anodes to extend asset integrity, grounding and their importance in the solar industry.

Understanding Cathodic Protection:

Cathodic protection is a technique used to control the corrosion of a metal surface by making it the cathode of an electrochemical cell. Magnesium drive-in anodes, a type of sacrificial anode, are integral to this process, especially in the instance of protecting buried steel structures eg; solar panel support brackets.

Magnesium Drive-In Anodes:

Manufactured to meet stringent ASTM B843 standards, magnesium drive-in anodes come in two potential variants: high potential (ASTM B843-M1C) and standard potential (ASTM B843-AZ63B). The high potential anodes are designed for soils with resistivity’s exceeding 2,000 Ω·cm, while standard potential anodes are ideal for resistivity’s under 20 Ω·cm. the anodes are installed to protect the metallic structure from corrosion whilst providing grounding path.

Composition and Performance:

The chemical composition of these anodes varies based on the required potential. High potential anodes contain minimal aluminum (0.01% max) and silicon (0.05% max), while standard potential anodes have higher aluminum (5.30%~6.70%) and zinc (2.5%~3.5%) content. This composition affects the electro-potential options, with high potential anodes offering a nominal corrosion potential of -1.7 to -1.75 volts, and standard potential anodes at -1.55 volts, relative to a Cu/CuSO4 reference electrode.

Applications in Solar Panel Systems:

Magnesium anodes are widely used for the cathodic protection of buried steel structures, which includes solar panel support brackets, gas service entrance piping, and gas distribution risers. Their role is to prevent corrosion, thus extending the lifespan of these components. Magnesium drive-in anodes play a crucial role in the maintenance and durability of solar panel infrastructure. By understanding their function, composition, and application, stakeholders in the solar industry can ensure the longevity of their investments and contribute to the sustainable growth of renewable energy.

Contact our Florida office for Cathodic Protection Products and support for more details on magnesium drive-in anodes and their applications, +1 772 646 2873 or [email protected],

https://cathtectusa.com/cathodic-protection-products/anodes/?swcfpc=1

Or Request a quote [email protected] and our technical sales team will be happy to answer any questions and assist you in choosing the right anode for all your corrosion protection application.